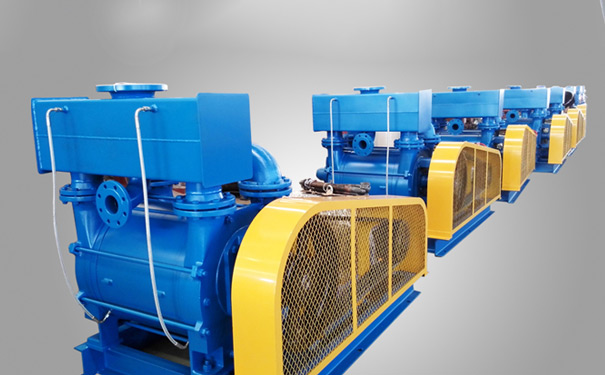

2BE1 Liquid ring vacuum pump and compressor

- 2BE1 Liquid ring vacuum pump and compressor

■Feature:

● Upper-type gas water separator design, saving space and reducing noise effectively.

● Reserved suction and exhaust flange on the side makes installation simple and convenient.

● All bearings are imported from Germany, ensuring stable space between impeller and the disc, accurate positioning of the impeller, high stability and sustainability of equipment during the operation.

● The sleeve is made of high chromium stainless steel to improve the service life.

● Pump pulley and clamping set takes the implementation of export standards.

● Diverse material selections of pump body, high-precision CNC machining.

● Castings are manufactured according to export standards, all use resin sand casting, annealing treatment.

● Ductile iron casting or steel plate welding and high temperature solid solution are used for all impellers, which ensure the stability of 2BE1 vacuum pump impeller working in a variety of harsh conditions and improve the service life of 2BE1 vacuum pump.

● Mechanical seals (optional) are all imported parts.

● Vacuum pump parts can be exchanged with the same model ones of the foreign equipment.

●The supplying range of pumps can be flexibly chosen according to customers’ requirements:

■ Overview

VOLM 2BE1 series vacuum pump exhaust system takes in a unique PTFE valve plate structure (the original one is ball valve structure). It is covered on the outside vent hole of the disc and is positioned by stainless steel baffle on the other side. The valve plate changes its bending degree with the change of the inlet pressure so that the pumping medium can be exhausted when reach the customized inlet pressure. This structure avoids overcompression in the vacuum system, which automatically adjusts the exhaust area to reduce energy consumption, so as to result in optimum operating efficiency. This series of pumps are with single-stage single-action structures, having the advantages of simple structure, easy maintenance, reliable operation, energy efficient and so on. Compared with the current widely used SK, 2SK, SZ series of water ring vacuum pump, this series have advanced technology, high vacuum, low power consumption, reliable operation and other significant advantages, and are ideal alternative products.

■ The supplying range of pumps can be flexibly chosen according to customers’ requirements:

Pump head: including the upper-type separator, connecting pipe.

Whole set of the machine: including the pump head, the upper-type separator, connecting pipe, motor, chassis, hood, pump and motor connector or pump pulley, belt.

Vacuum pump unit: including vacuum pump machine, gas-water separator, check valve, bellows and connected piping, electrical contact vacuum gauge, auto-decompression starting cabinet.

Complete sets of equipment: including the whole set of vacuum pump machine, gas-water separator (with level gauge), heat exchangers, valves, normally closed valves, filters, vacuum gauge, pressure gauge, pipe, electric control cabinet.

Inlet pressure below 33 mbar (absolute), 2 stages or multi-stages vacuum system (water ring - Roots unit) will be in use.

● Varied transmission methods, such as: Coupler driving, pulley driving, reducer driving.

● Stainless steel materials (304, 316L) or special ones can be chosen according to the corrosion of media; Packing seals and mechanical seals or others can be provided on request.

■ Applications

2BE1 series of products have a wide range of applications, such as the condenser vacuum suction, desulfurization device in fly ash treatment, acetylene and other flammable and explosive special gas compression, ozone compression, pulp and paper, gas recovery, soil purification, disinfection , dehydration, Filtration, extrusion / vacuum forming, dipping, extraction, pressure swing adsorption decarbonization, hydrogen extracting, oxygen producing, purification and so on.

■ Technical Data

| Model No. | Speed(Driving Method)r/min | Motor Power(kW) | Motor 380V | Ultimate Vacuum mbar | Max. Air Suction Rate | Weight(Whole Set)kg | |

| m3/h | m3/min | ||||||

| 2BE1 102 | 1450 1450 | 5.5 7.5 | Y132S-4 Y132M-4 | 33mbar (-0.098MPa) | 235 235 | 3.9 3.9 | 252 265 |

| 2BE1 103 | 1450 1450 | 7.5 11 | Y132M-4 Y160M-4 | 33mbar (-0.098MPa) | 405 405 | 6.8 6.8 | 291 333 |

| 2BE1 152 | 1450(直联) 1100(皮带) 1300(皮带) 1625(皮带) 1750(皮带) | 15 11 15 18.5 22 | Y160L-4 Y160M-4 Y160L-4 Y180M-4 Y180L-4 | 33mbar (-0.098MPa) | 465 340 415 510 535 | 7.8 5.7 6.9 8.5 8.9 | 481 437 481 515 533 |

| 2BE1 153 | 1450(直联) 1100(皮带) 1300(皮带) 1625(皮带) 1750(皮带) | 18.5 15 18.5 22 30 | Y180M-4 Y160L-4 Y180M-4 Y180L-4 Y200L-4 | 33mbar (-0.098MPa) | 600 445 540 660 700 | 10.0 7.4 9.0 11.0 11.7 | 533 480 533 551 601 |

| 2BE1 202 | 970(直联) 970(直联) 790(皮带) 880(皮带) 1100(皮带) 1170(皮带) 1300(皮带) | *18.5 22 15 18.5 30 30 37 | Y200L1-6 Y200L2-6 Y160L-4 Y180M-4 Y200L-4 Y200L-4 Y225S-4 | 33mbar (-0.098MPa) | 760 760 590 675 850 890 950 | 12.7 12.7 9.8 11.3 14.2 14.8 15.8 | 916 926 830 850 940 945 995 |

| 2BE1 203 | 970(直联) 790(皮带) 880(皮带) 1100(皮带) 1170(皮带) 1300(皮带) | 37 22 30 37 45 55 | Y250M-6 Y180L-4 Y200L-4 Y225S-4 Y225M-4 Y250M-4 | 33mbar (-0.098MPa) | 1120 880 1000 1270 1320 1400 | 18.7 14.7 16.7 21.2 22.0 23.3 | 1065 930 995 965 1080 1170 |

| 2BE1 252 | 740(直联) 565(皮带) 660(皮带) 820(皮带) 885(皮带) 920(皮带) | 45 30 37 55 55 75 | Y280M-8 Y200L-4 Y225S-4 Y250M-4 Y250M-4 Y280S-4 | 33mbar (-0.098MPa) | 1700 1230 1500 1875 2000 2080 | 28.3 20.5 25.0 31.3 33.3 34.7 | 1693 1460 1515 1645 1645 1805 |

| 2BE1 253 | 740(直联) 740(直联) 565(皮带) 660(皮带) 820(皮带) 880(皮带) 920(皮带) | *55 75 45 55 75 90 90 | Y315S-8 Y305M-8 Y225M-4 Y250M-4 Y280S-4 Y280M-4 Y280M-4 | 33mbar (-0.098MPa) | 2450 2450 1750 2140 2690 2860 2980 | 40.8 40.8 29.2 35.7 44.8 47.7 49.7 | 2215 2369 1695 1765 1950 1955 2055 |

| 2BE1 303 | 590(直联) 740(直联) 472(皮带) 500(皮带) 530(皮带) 590(皮带) 660(皮带) 710(皮带) 740(皮带) 790(皮带) | 75 110 55 55 75 75 90 90 110 132 | Y315L2-10 Y315L2-8 Y250M-4 Y250M-4 Y280S-4 Y280S-4 Y280M-4 Y280M-4 Y315S-4 Y315M-4 | 33mbar (-0.098MPa) | 3200 4000 2600 2700 2880 3200 3600 3820 4000 4200 | 53.3 66.7 43.3 45.0 48.0 53.3 60.0 63.7 66.7 70.0 | 3080 3160 2645 2645 2810 2810 2925 2925 3179 3290 |

| 2BE1 353 | 590(直联) 372(皮带) 420(皮带) 472(皮带) 500(皮带) 530(皮带) 590(皮带) 660(皮带) | 132 75 75 90 110 110 132 160 | Y355L1-10 Y280S-4 Y280S-4 Y280M-4 Y315S-4 Y315S-4 Y315M-4 Y315L1-4 | 33mbar (-0.098MPa) | 5300 3480 3760 4200 4500 4730 5300 5780 | 88.3 58.0 62.7 70.0 75.0 78.8 88.3 96.3 | 4750 3560 3600 3665 3710 3905 4750 4100 |

*The data marked by * is suitable for special processing.

For more detailed information, please contact us.